EMARK solutions for manufacturing

Bolster your business with our rich experiences from the manufacturing area.

EMARK solutions for manufacturing

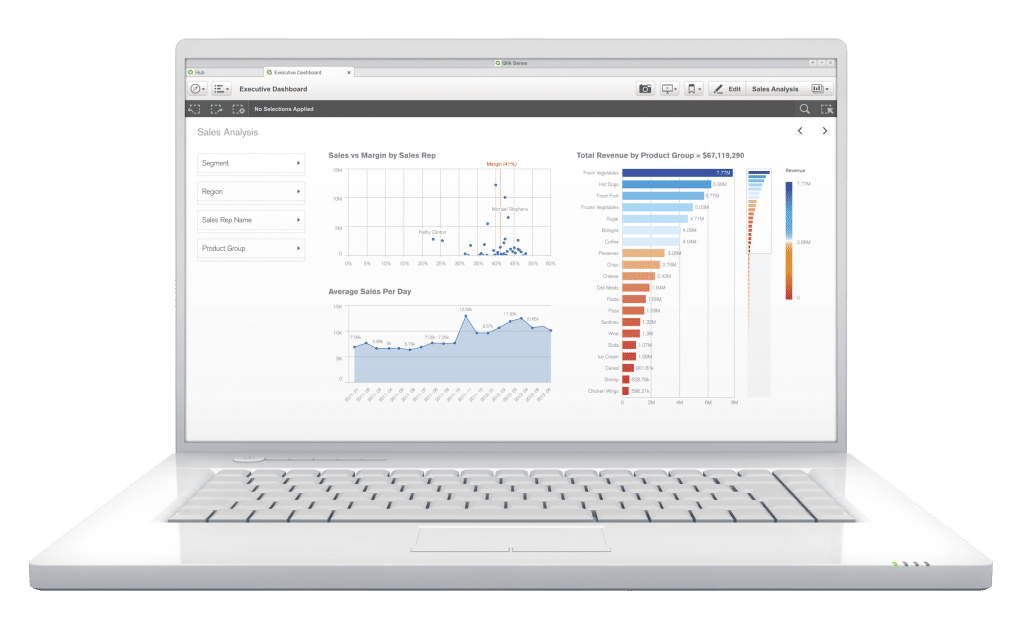

Back your business with fast and reliable decisions. With proper solutions for manufacturing, it is easier than you think. It could work more swiftly, effectively and smarter. Get real-time insights to production or supply chain. Measure and increase your operational effectiveness.

Do you ask how to use production lines to full capacity and retain a high level of productivity? Do you think of how to keep the costs under control over costs, while retaining high-quality standards? Or eventually how to synchronize particular production elements and inputs or how to avoid slowing down the production process, downtime or error rate? We have proven solutions built on Qlik technologies and vast experiences from the area. Check how our solutions for manufacturing can help you.

Data Driven Approach to Industry 4.0

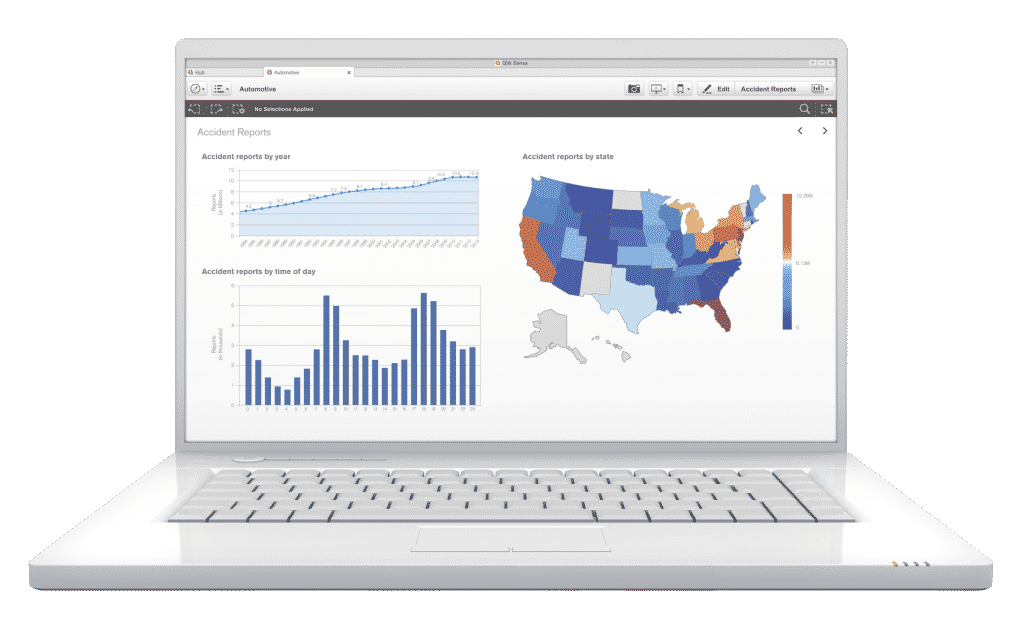

Transform your business with faster, fact-based decisions. Qlik helps manufacturing organizations use data to optimize processes, improve supply chain agility, and better serve the modern customer.Areas where you can use EMARK solutions for manufacturing

Planning

Logistics

Marketing

Purchasing

Finance

Controlling

Information technologies

Top management

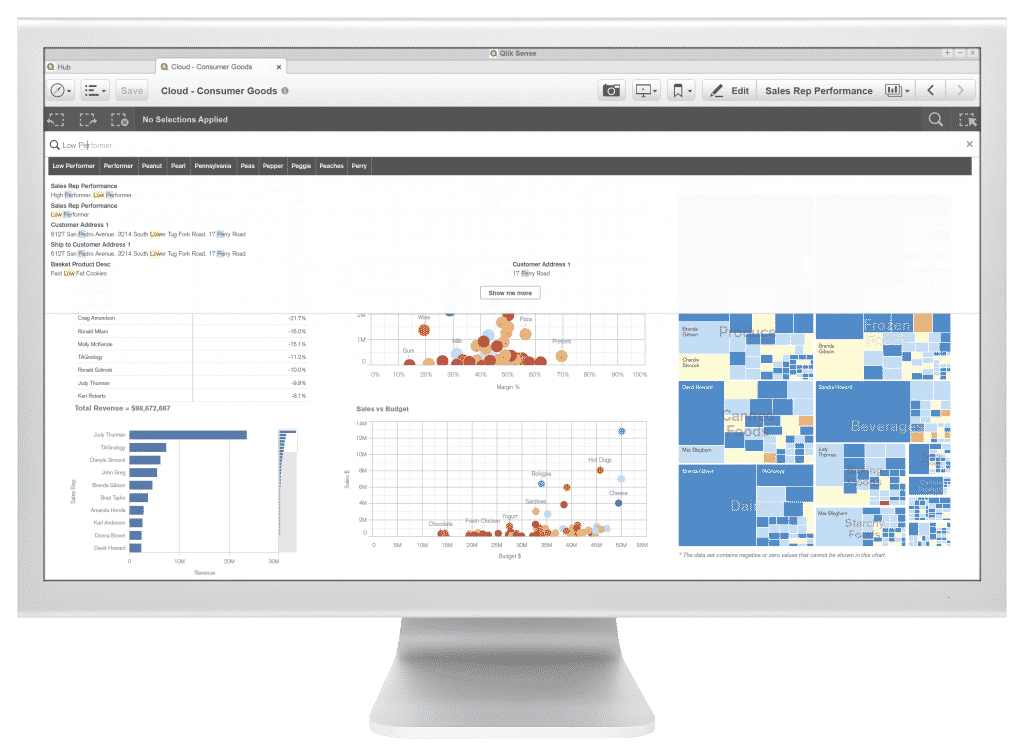

Connecting worlds

Big advanted of our solutions is ability to collaborate with existing systems such as SAP. We are able to connect them to particular moduls – production, controlling, finance, logistics or material and more.

This solution is not only the fastest in terms of obtaining data, but also from the implementation point of view. It is not about replacing existing IT systems, but about maximizing their value.

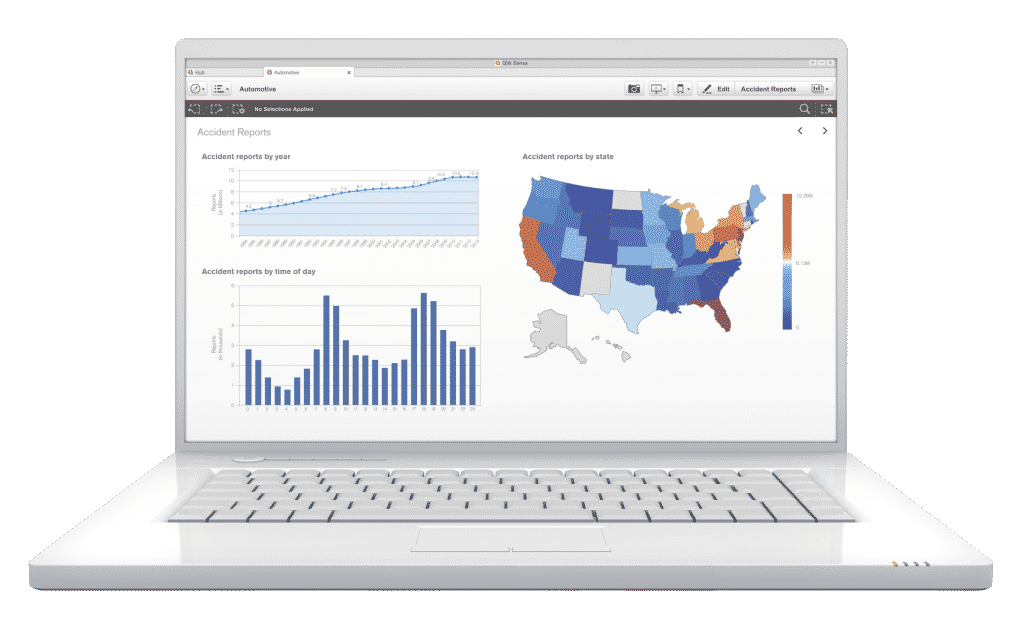

Live view on production

You will see exactly those information you need, without delays. Performance of particular site clerks, engineers or even whole shifts, number of produced items, material structure, stock and vast amount of other information – all of this you can have on one screen and only few clicks away.

In the real time you can monitor usage of production lines vs. plan which gives the power to optimize production while running.

Massive support for logistics

Logistics works with broad range of various information – orders from CRM, stock from warehousing system, production plan or transportation record and distribution. Manual intervention linked with this are often a source of inaccuracies and down-time.

We could help you to eliminate them, so you only have to add inputs to the system based on orders and business plan. System will subsequently plan the production, volume of material on stock or in example safety stock.

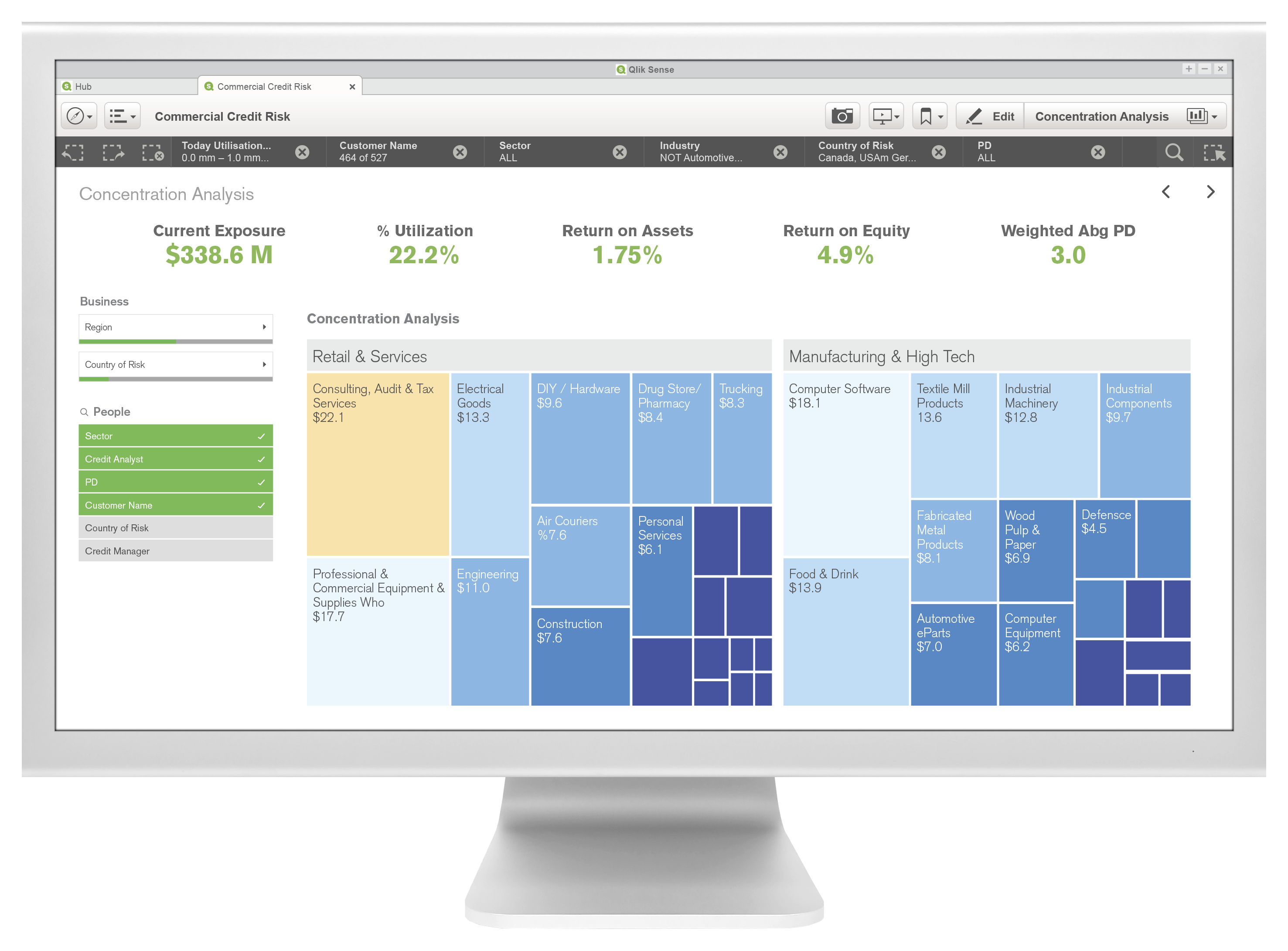

Optimal production plans

By automating of the planning process we can help you to avoid overloading of planners – in some cases by as much as 95 %. These plans are taking into the account huge amount of parameters which are selected by you or we can advise on this – production lines, bottlenecks, size of warehouses, packing or transportation capacities, stock, size of labor force and many other parameters such as energies, material or regulations and legislation.

Just enter the base data and all the details will automatically calculate the model. Immediately you will see changes translated to the utilization of capacities and eliminating bottlenecks across the production program.

Simuations and what-if scenarios

Our technologies will enable you to simulate various scenarios, e.g. lower or higher volume of orders, stock, capacities etc.

Responsible workers could thusly optimize utilization of devices or labour force and eliminate risks connected with down-time or expiration and plan the production accordingly.