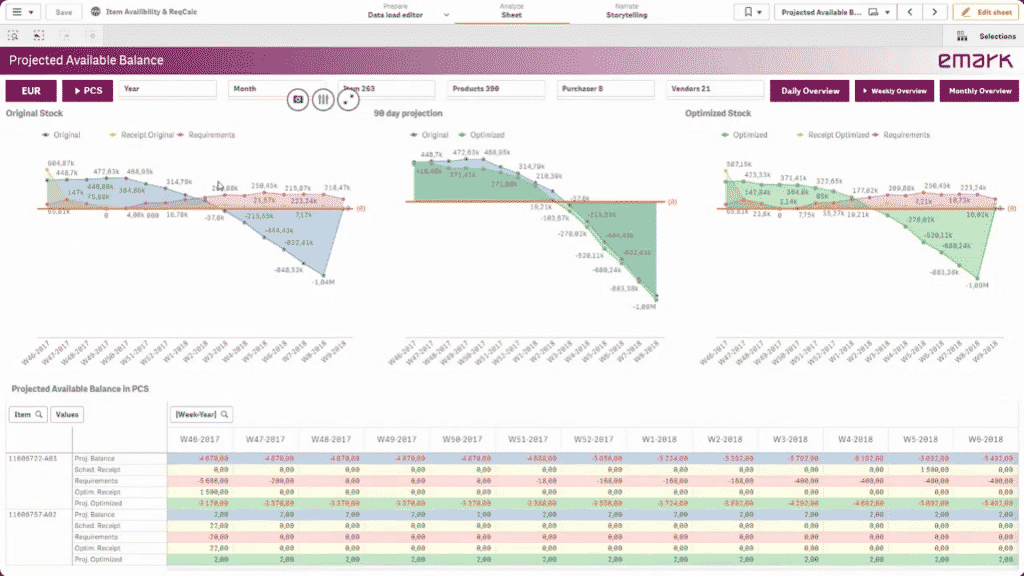

Projection of material or item availability and production planning

How to reach smooth logistics and production without down-time?

Production inputs ready just when you need it to secure smooth production

Managers in production often have to resolve issues with missing material inputs which causes production to delay the delivery of the products to the customer. Or, if material supplies are delayed it is difficult to predict when the product will actually be delivered to the client.

We can help you to resolve all the issues with the availability of material or goods – without compromising the production continuity, or sales. Our powerful apps will secure that all the production inputs will be at disposal just-in-time and will also help you to plan production and downtime effectively.

A few happy clients

How?

UNLOCK YOUR DATA

- Connect data from all source systems

- Create associative data model

- Do any ad-hoc self-service analysis in Qlik

GET SUPERFAST INSIGHT

- Ready-made apps & custom dashboards

- Model, plan, set targets & alerts

- Drill-down across all business areas

UNDERSTAND AND ACTION

- Consult with certified financial expert

- Understand what your data tells you

- Set the right strategy & actions

- Monitor key KPIs

Increase performance and resiliency of your production or supply chain

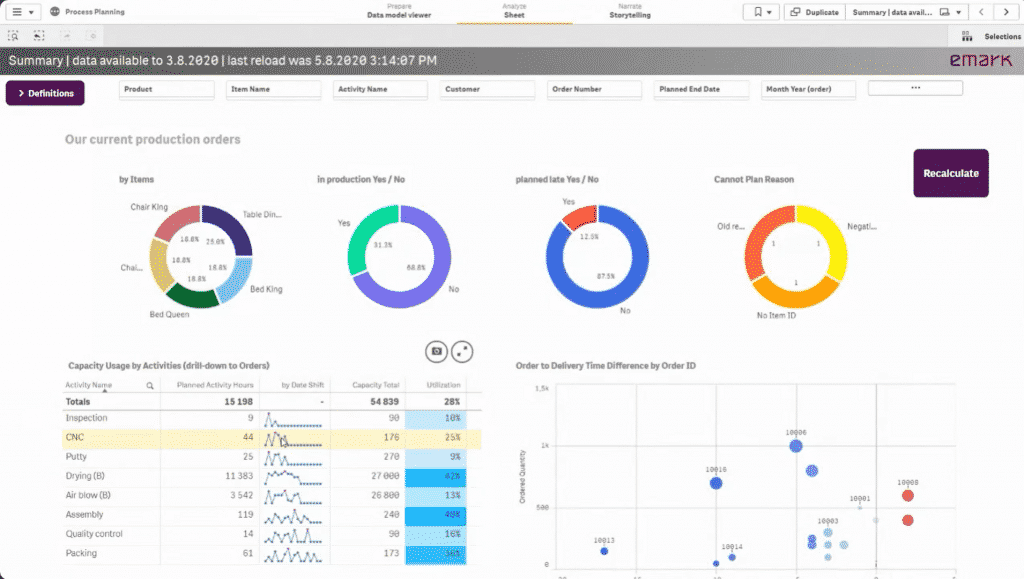

Join companies like Foxconn, Ahold, or Faurecia, who use data analytics to overcome availability issues, avoid delayed delivery, decrease cash tied to unnecessary stock, improve process stability, and plan ahead to increase customer satisfaction and profitability. We help companies to maximize value from data and start using data analytics fast with the help of our rapid solutions for material availability, process planning, stability analytics, and many other use-cases in process improvement.Process Stability and Capability Analysis

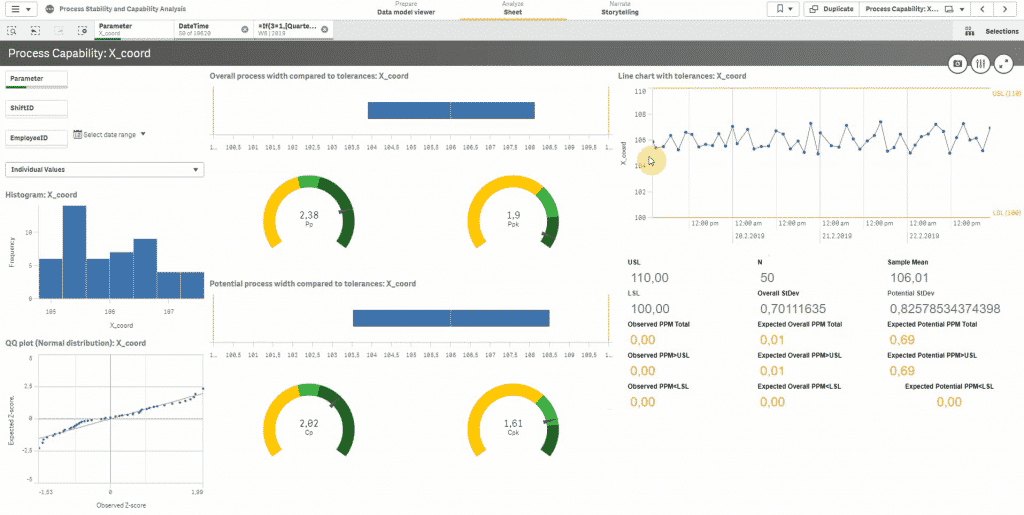

App for all those who need to report the stability of the processes and capacity, or want to know every single process step.

- dynamic selection of process parameters and instant result

- analysis of arbitrary parameters – period, shift, worker – seek the improvement potential

- automatic selection of correct control chart (I-MR, Xbar-R, Xbar-S) – evaluate of process stability based on data structure

- history of anomalies in the process and change of stability test parameters

- comparison of quarters, months, weeks or days to reveal maximum of out of control components. Process capacity in time